SSEC 3302

SSEC 3302

Contact us for price

or

Call +353 (0) 87 192 1110

Description

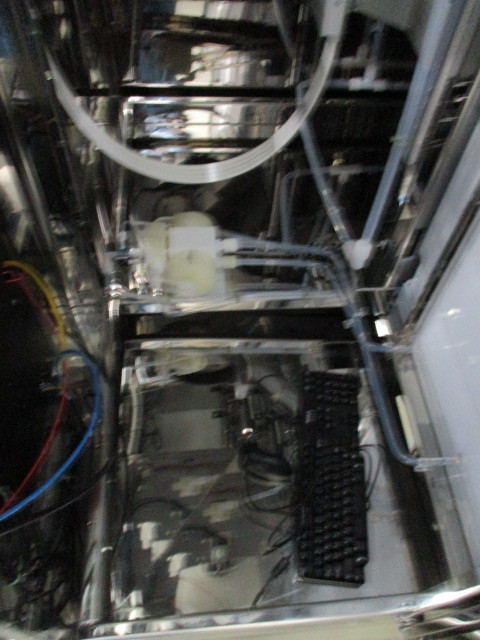

Two wafer processing modules, acid processing.

Stainless steel construction.

Two wafer elevators.

PC controller.

Currently configured for 200mm wafer sizes

MFG Date: 2010

CE Marked

(2) 200mm Horizontal Open Cassette stations

Integrated wafer sensor & teaching system

Non-contact wafer alignment system (optical alignment)

Dual blade wafer handling robot (PVDF coated ceramic end-effectors)

Process Stations:

Molded (HALAR), Etch & Clean processing chambers

WaferChek real-time process monitoring & control

Chemical Delivery System:

(3) Programmable fan dispense arms w/100% surface coverage

ARM-1: DI:CO2

ARM-2: DI Rinse, Stream

ARM-3: electronic, heated, filtered, N2 blow assist

Programmable chamber wash w/DIW

Chamber wall dispense w/adjustable nozzle

Internal open & closed chemical collection ring (prog. separation, open, or closed)

N2 or CDA Heater for gas seal spindle tooling

Spindle system: programmable, brushless direct drive closed loop spin motor

PC controlled chemical mixing for DI:CO2 solution

Non-contact resistance monitor for fresh DI:CO2 dilution feedback

PC programmable DI:CO2 re-circulation system

DI:CO2 re-circulation cleanliness & temperature control

(2) Automatic, programmable pressure & flow control systems – 1 per process chamber

Programmable flow rate monitoring systems

Programmable Chemical counting systems

SQL Process view Package

SECS II/GEM interface

Host emulation software – SECS II/GEM data collection on local PC as “Host”

Damaged / Missing Parts: None reported. Please inspect to confirm

Note: This tool is in new condition. It was installed & set-up in a new lab for development

but, was never used

Specifications

| Manufacturer | SSEC |

| Model | M3302 |

| Condition | Used |

| Stock Number | GOD19032019 |