Disco DFP8140 Fully Automatic Polisher

Disco DFP8140 Fully Automatic Polisher

Contact us for price

Description

Disco DFP8140 Fully Automatic Polisher For sale is a Disco DFP8140 Fully Automatic Polisher selling as is. It can power on and initialises with no errors. Contact us with your inquiry if your interested in buying this machine or any other machine. Chemical and slurry free polishing Improved yield Relieve wafer stress without slurry, chemicals or water. The DFP8140 effectively removes the grinding induced damage layer by utilizing a dry polishing process. This process greatly reduces warpage and the chance of wafer breakage while improving die strength. The end result is superior product yield, even for today's ultrathin wafers. In-line system The DFP8140 design allows it to be integrated with DISCO grinders for an in-line wafer thinning solution that grinds, dry polishes, and transports wafers safely and securely (the in-line system requires the installation of optional accessories). Environmentally friendly process Unlike chemical etching or CMP, the dry polishing process does not require costly waste treatment and disposal. Dry polishing with the DFP8140/8160 is environmentally friendly while maintaining a lower cost of ownership than other stress relief processes. Easy operation The DFP8140/8160 utilizes the same operator interface and machine layout as the DISCO Fully Automatic Grinder (DFG8540/8560). This ensures reduced training time for operators familiar with DISCO equipment. For those new to the 8000 Series, the touch-screen graphical user interface with real-time process data makes both operation and maintenance tasks easy to learn and accomplish [av_ Environmental conditions • Use clean, oil-free air at a dew point of -15 ?or less. (Use a residual oil: 0.1 ppm Wt/Wt. Filtration rating: 0.01 ?m/99.5 % or more). • Keep room temperature fluctuations within ±1 ?of the set value. (Set value should be between 20 -25 ?). • Keep grinding water + 0 -2 ?above room temperature (fluctuations within 1?over one hour) and cooling water between 20 ?-25 ?(fluctuations within 2?over one hour). • Keep spindle cooling water temperature between 20 -25 ?(fluctuations within 2 ?over an hour). • The machines should be used in an environment, free from external vibration. Do not install machine near a ventilation opening, heat generation equipment or oil mist generating parts. • This machine uses water. In case of water leakage, please install the machine on the floor with sufficient waterproofing and drainage treatments. * All the pressures are described using gauge pressure. * The above specifications may change due to technical modifications. Please confirm when placing your order. * For further information please contact your local sales representatives.

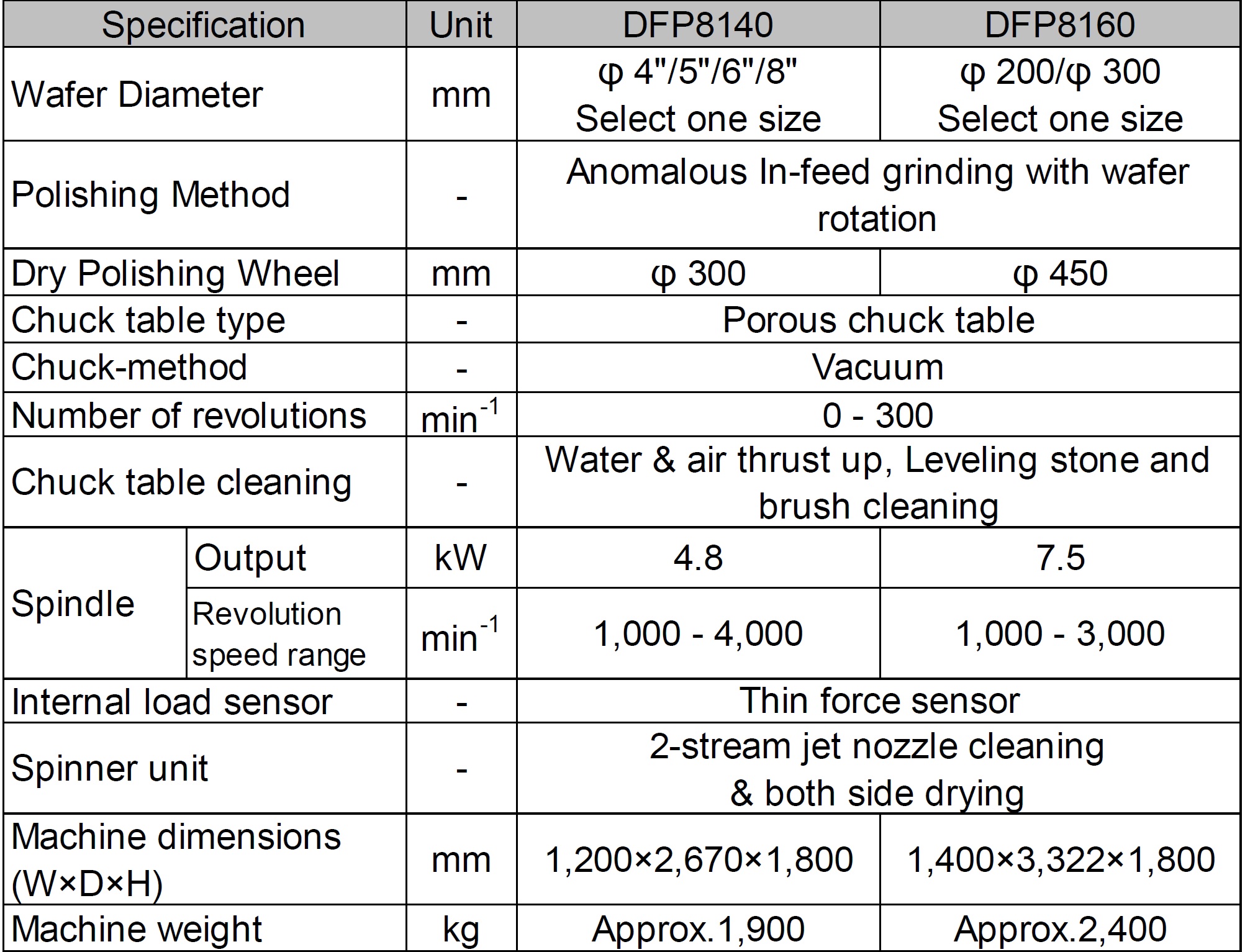

Specifications

| Manufacturer | DISCO |

| Model | DFP8140 |

| Year | 2005 |

| Condition | Used |

| Stock Number | GOD04022020 |