2008 DNS SU3000

2008 DNS SU3000

Contact us for price

Description

With Software and HDD

As Is

General Data

Wafer size 300 mm

Number of Chambers 4

Handling Frontside / Back Side Revese unit : 2 unit

Number of loadport 4

Number of Chemical Cabinet 3 (CC1, IPA , E-FLOW) CC1 HF , BOE, IPA)

Overhead Transport System (OHT) Yes

Indexer Unit

Load port

ID/R

Manufacture Yasukawa Electric Corp.

Model No. XU-ACT153L-B01

FFU HITACHI (High Efficiency Particulate)

Model No. 2T-445950GGE-SWALY

Material Fluoridation resin filter

Capacity of filter 99.995 <% or more of 0.1μm

Particle

Range of air control 0~0.4 m/sec

Transfer unit

CR

Manufacture Yasukawa Electric Corp.

Model No. XU-RC615L-A12

FFU

Model No. 2T-445950GGE-SWALY

Material Fluoridation resin filter

Capacity of filter 99.995<% or more of 0.1μm

particle

Range of air control 0~0.6 m/sec

PROCESS CHAMBER MPC chamber 1,2,3,4UNIT

SHIELD PLATE

Shield Plate IPA Dispense IPA

Shield Plate DIW Dispense CO2 WATER

Shield Plate Nozzle Drain CO2 WATER

Shield Plate Nozzle Drain IPA

SCAN NOZZLE-1

Scan Nozzle1 chem.2 Dispense DHF

Scan Nozzle1 DIW Dispense CO2 WATER

Scan Nozzle1 chem.4 Dispense BULK HF

Port 20 DHF Reclaim line v/v open DHF

Port 21 ACID Drain line v/v close ACID

Port20 N2 Purge N2

Scan Nozzle1 chem.2 Nozzle Drain DHF

Scan Nozzle DIW&CHEM.4 Nozzle Drain CO2 WATER & BULK HF

SCAN NOZZLE-2

Scan Nozzle DIW Dispense CO2 WATER

Nano Spray N2 N2

Nano Spray DIW Dispense CO2 WATER

Nano Spray chem.3 Dispense SC-1

Nano Nozzle2 chem.3 Dispense SC-1

Nano Spray Composite N2 & CO2 WATER

Nano Spray Composite N2 & SC-1

Scan Nozzle2 chem.3 Nozzle Drain SC-1

BACK SIDE NOZZLE

Back Side Nozzle chem.2 Dispense DHF

Back Side Nozzle chem.3 Dispense SC-1

Back Side Nozzle DIW Dispense CO2 WATER

Back Side Nozzle5 CHEM.4 Dispense BULK HF

Back Side Umbrella Nozzle Dispense CO2 Water

Back Side Nozzle Pre Dispense ALL

Back Side Nozzle Drain ALL

FIXED NOZZLE

Chuck Rinse Nozzle Dispense CO2 WATER

Spin base Rinse Nozzle Dispense CO2 WATER

Shield Plate Surface Rinse Nozzle Dispense CO2 WATER

Fixed Nozzle Dispense CO2 WATER

SPIN BASE

Material PCTFE

Spin motor AC servo motor

Revolution Max.3000rpm

Acceleration Max. 1000rpm/sec

Revolution accuracy ±3rpm (at 3000rpm)

CHUCK

Chuck drive Pulse motor

Material PCTFE, ETFE

Wafer detection Detection by chuck pins (by

photo sensor)

SHIELD PLATE

Material HT-PVC

Revolution drive AC servo motor

Revolution Max.3000rpm

Acceleration Max. 1000rpm/sec

Revolution accuracy ±3rpm (at 3000rpm)

Up/down shift AC servo motor

Distance to the wafer surface Min.0.3mm

SPLASH GUARD

Structure Chemical collection

Material PTFE

Up/down shift AC servo motor

SHUTTER

Drive Air cylinder

CHEMICAL CABONET-1,2 Temperature control of low temperature

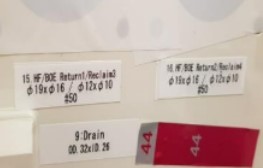

Chemical used HF , BOE

Chemical mixing ratio Premix

Range of temperature control 20~35℃

Chemical Filter CHEMLOCK HOUSING

0.1μm

Circulation Pump PILLAR

Circulator KOMATSU

NES-2123-7

Temp Controller KOMATSU

GRS-612

E-FLOW

Module SD16L-24S W

Resistivity Meter OE-960CE (HORIBA)

Resistivity Sensor ESD-001C-T

Sensor Cable CK-10M

Sensor Holder EFA-30

Relay MY2N-CR DC24V

Specifications

| Manufacturer | DNS |

| Model | SU3000 |

| Year | 2008 |

| Condition | Used |

| Stock Number | BM2265 |