TEL ACT-12_3C4D

TEL ACT-12_3C4D

Contact us for price

Description

Coater/ developer

No missing/ complete

De-installed

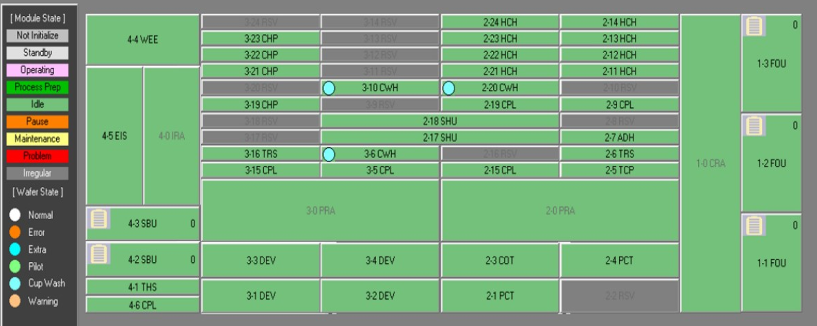

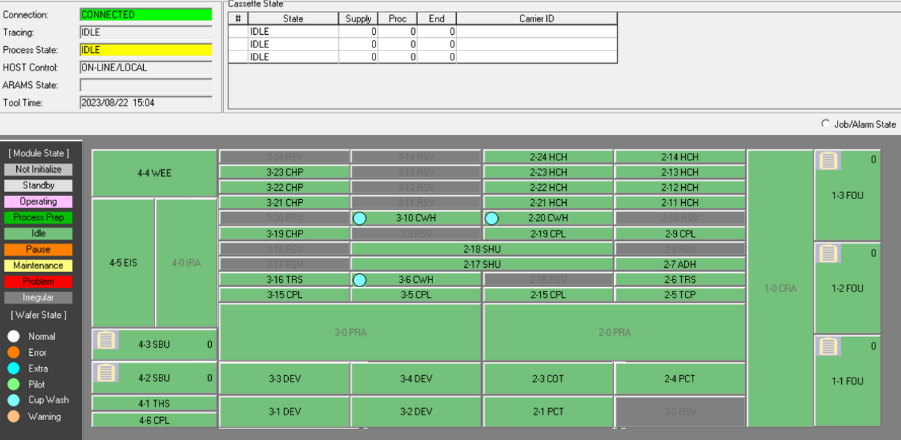

Manufacturer: TEL ACT12-300 Dual Block Track

Tool Type: Dual Process Block Track

Model: ACT12-300

Wafer Size: 300mm

Direction: RIGHT HAND SIDE

4 Blocks Interfaced; Cassette, 2 Process, & Stepper Interface

4 Wafer Transfer Robot Arms; Cassette, 2 Process, & Stepper Interface

Control Module on cassette end station (CES)

3 Station 25 wafer FOUP

Interface is to Ultratech T-300

Cassette rotators and platforms

Facility sensors for DI water and Caustic exhaust

Coater (COT) - quantity 1

Coater (PCT) - quantity 2

2 Nozzles w/ Temperature Control

Chuck vacuum sensor

Millipore P-250 pumps

SS 0.3mm diameter side rinse nozzle w/ flow meter

1 set of 2 SS 0.3mm diameter back rinse nozzles

1 SS 0.3mm diameter back rinse nozzle for chemical 1

1 SS 0.3mm diameter back rinse nozzle for chemical 2

Bulk-FSI system for side and back rinse

PTI mass flow controller per module

PP cup w/ sensor

Chuck Up VAC Off Switch

Addition of drip trays

Developer (DEV) - quantity 4

1 “H” nozzle w/ temperature control per cup

Bulk-FSI system for developer

PP cup w/ sensor

Chuck vacuum sensor

Chuck Up VAC Off Switch

Chill Plate Process Station (CPL) - quantity 6

Hard anodized aluminum oxalic acid treated surface plate AL

Temperature Control

0.1 mm C ring fixed type and spacer type stainless & polyimide proximity pins

Dual-Band alarm function

Transfer Chill Plate (TCP) – quantity 1

Hard anodized aluminum oxalic acid treated surface plate Al

0.1mm C ring fixed type and spacer type stainless & polyimide proximity pins

Adhesion Process Station (ADH) – quantity 1

Half-sealed chamber w/ dispersion plate for HMDS

Dual-band alarm function

10L canister w/ Bubble sensor

Heated Cover High Exhaust Low Temp Hot Plate Process Station (HCH) - quantity 8

N2 purge capability

High volume exhaust

Mist traps

SS insulated heated exhaust cover w/ cover interlock

Hard anodized aluminum oxalic acid treated Al surface plate

Temperature control

0.1mm C ring fixed type and spacer type stainless & polyimide proximity pins

Dual-band alarm function

Individual thermo-switch for overheating detection

Interface Block - quantity 1

Single-pincette shared wafer transfer w/ centering guides; standard wafer arm and interface panel to accommodate Ultratech T-300 (May vary)

Interface must include a CPL for insuring consistent wafer temps into the stepper; (IFCPL)

Buffer cassette; 26 wafer capability

Wafer out sensor

WEE requires 435nm spectrum for G-line application

TEL Temperature and Humidity Controller - 2

Fluid Temperature Controller – 1

Chemical Cabinet – 1

DI H20 facility sensors

4- 1gal C4 bottles w/ recirculation feature

2- 20L reserve Tank s w/ 2- 3L buffer tanks for solvent

2- 20L reserve Tank s w/ 2- 3L buffer tanks for develop

300cc L/E for solvent

8- 200cc L/E for C4

1- Solvent panel

1- Develop panels

2- auto change air valves

AC Power Box – 1

Specifications

| Manufacturer | TEL |

| Model | ACT-12_3C4D |

| Condition | Used |

| Stock Number | BM3586 |