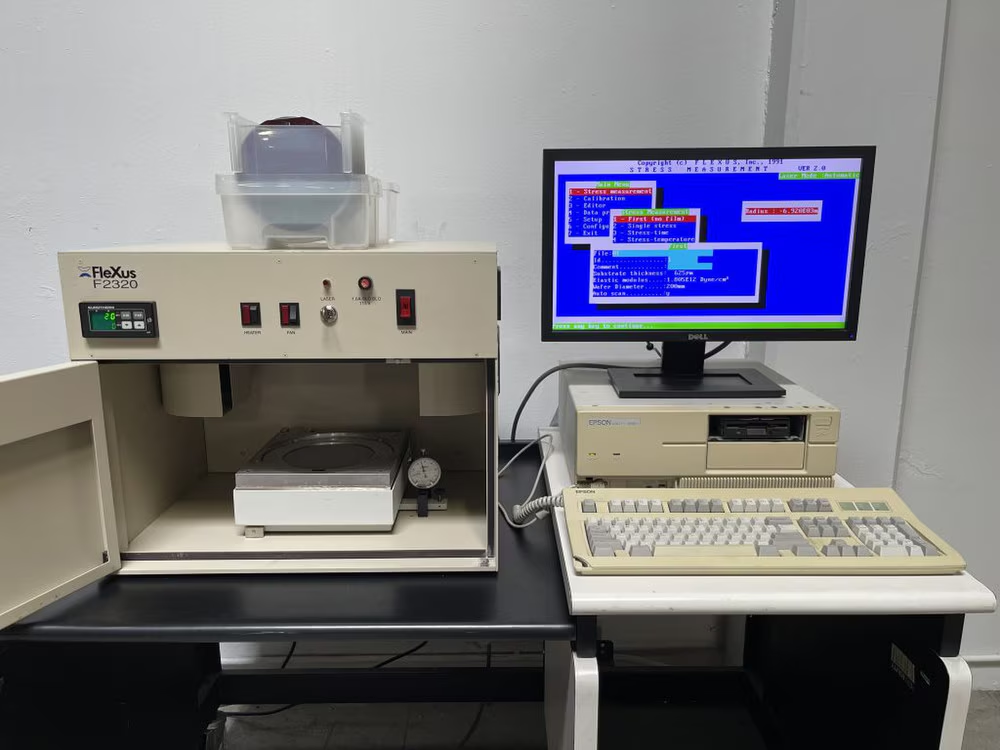

KLA Flexus FLX2320

KLA Flexus FLX2320

Contact us for price

Description

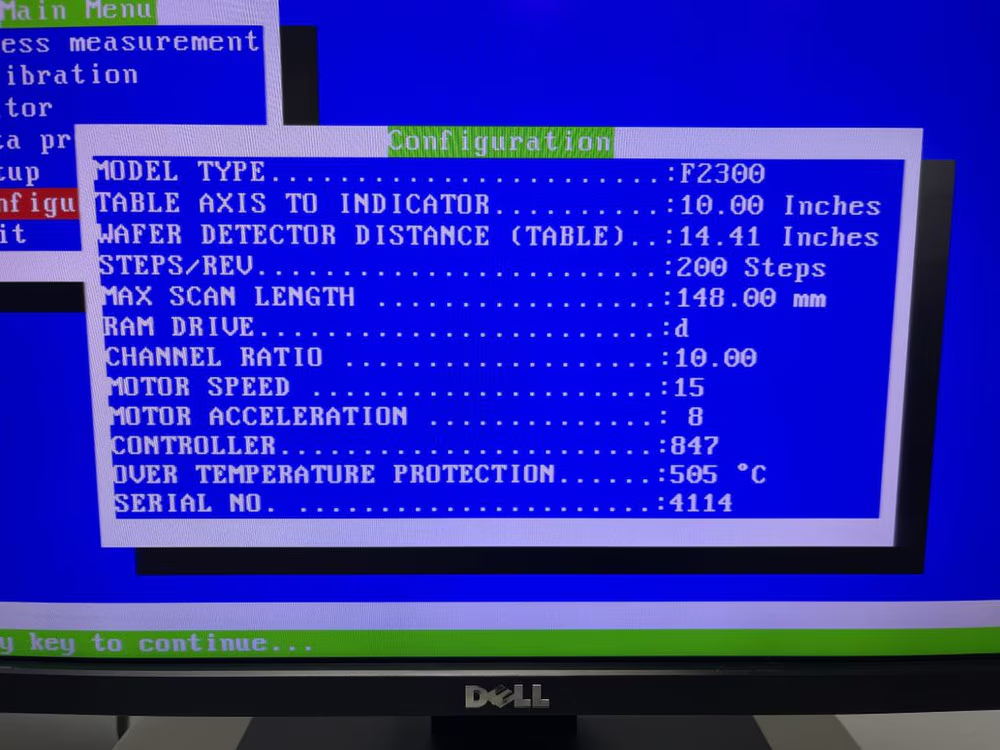

KLA-TENCOR FLX-2320 FILM STRESS MEASUREMENT SYSTEM consisting of:

- Model: FLX-2320I

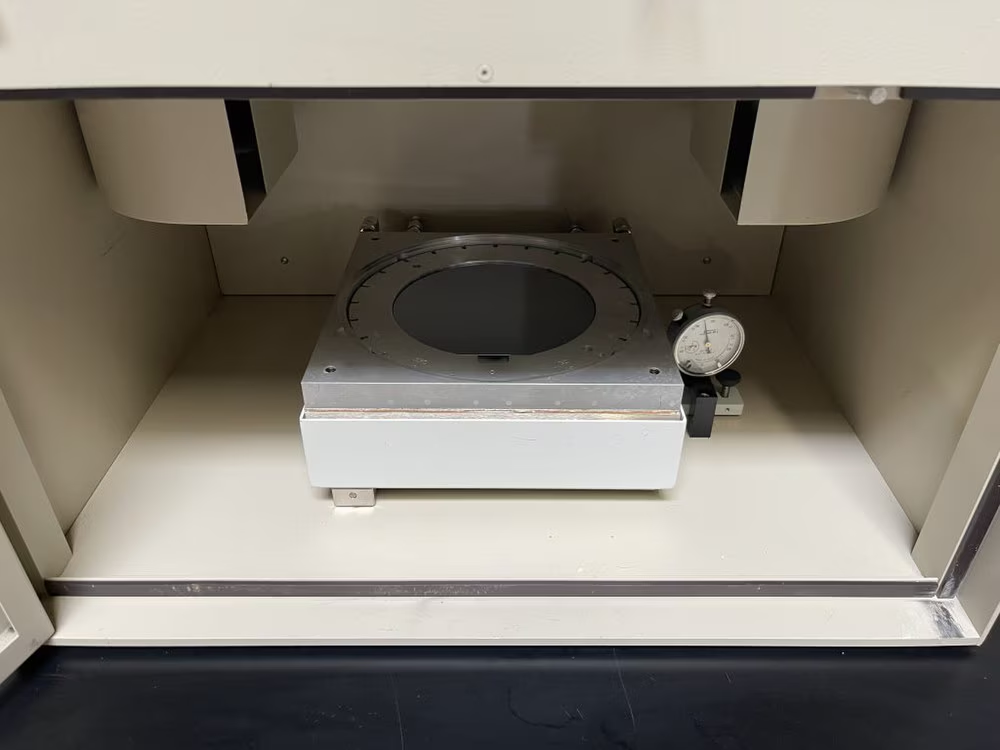

- Manual Wafer Load

- Thin Film Stress Measurement System

- Chuck Size can be configured for up to 8“ wafers

- Temperature: up to 500C

- Dual Wavelength Technology

- Operating System: MS-DOS V6.22

- Software Version 2.0

- Operations Manual and Documentation

- 6 Month Warranty

KLA-TENCOR FLX-2320 SYSTEM CAPABILITIES consisting of:

- Thin-film stress measurement instrument that measures the changes in the

radius of curvature of a wafer caused by the deposition of a stressed thin film.

- Laser scanning to measure stress on all reflecting films.

- Measures and displays stress as a function of time or temperature.

- Comprehensive data analysis capabilities that include trend plotting for

statistical process control (SPC) and displaying a 3-D map of wafer deflection

over the entire surface.

- Used for calculation of biaxial modulus of elasticity and linear expansion,

water diffusion coefficient in dielectric films, linear regression and stress-temp

or stress-time gradients.

- Provides analysis of thin film stress with very low measurement noise and

allows observation and quantitative evaluation of stress relaxation, oxide

densification, thin film phase transformations and annealing.

- NOTE: This system requires the use of reflective substrates to run the pre/post deposition measurements, transparent substrates will not work. In most cases customers use Si monitor wafers for stress measurement instead of product wafers.

KLA-TENCOR REFURBISHMENT PROCESS consists of:

- Replace used Laser with New Laser.

- Replace used Photomultiplier Tubes (PMTs) with Brand New PMTs, as

required.

- Replace used Power Supply, as required.

- Replacement or repair of any bad circuit board.

- Mechanical assemblies cleaned, lubricated, rebuilt, or replaced as needed.

- Optics assemblies cleaned and aligned to meet performance specifications

or replaced as needed.

- Electronic assemblies tested to meet performance specifications or replaced

as needed.

- Puck assembly rebuilt or replaced (if applicable).

- Replace old monitor with Brand New LCD Monitor.

- Calibrate system using calibration wafers.

- Machine covers are cleaned, polished, or replaced, as needed.

- Machine is fully tested.

- System de-installed following proper procedures.

- System transport locks installed; system prepared for shipment.

- Refurbishment carried out by KLA-Tencor trained technicians.

Condition:

Refurbished

Specifications

| Manufacturer | KLA |

| Model | Flexus FLX2320 |

| Condition | Used |

| Stock Number | BM5527 |