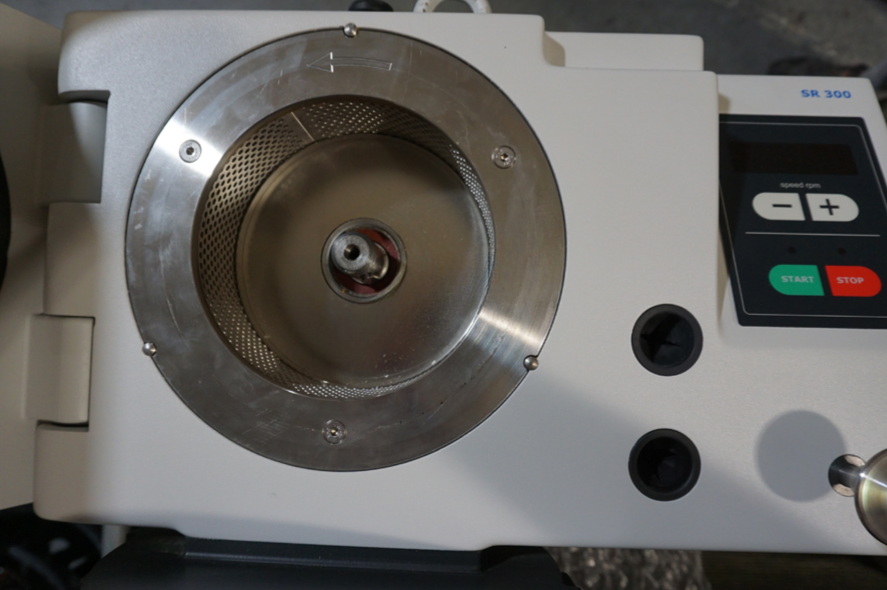

Retsch SR300 rotor beater mill

Retsch SR300 rotor beater mill

Contact us for price

Description

PRODUCT ADVANTAGES

- wide range of accessories including various feeding systems, rotors and sieves

- defined final fineness due to bottom sieves with aperture sizes from 0.08 - 10 mm

- optional grinding inserts 180° for grinding of hard-brittle materials by additional impact

- gravity outlet with 5l or 30 L collecting vessel for batchwise collection of larger sample quantities

- optionally available cyclone unit with 0.25 - 0.5 - 1 - 2 - 5 or 30 liters collecting vessel

- optional distance rotor to reduce frictional heat

- adjustable speed for different applications

- removable hopper for easy cleaning

- easy cleaning thanks to exchangeable push-fit grinding insert, rotor and cassette

- central locking device

- grinding chamber, feed hopper and material inlet and outlet made of stainless steel

- electric engine brake

FEATURES

Applicationssize reduction, deagglomerationField of applicationagriculture, chemistry / plastics, construction materials, environment / recycling, food, geology / metallurgy, medicine / pharmaceuticalsFeed materialsoft, medium-hardMaterial feed size*< 25 mmFinal fineness*< 50 µmSpeed at 50 Hz (60 Hz)3,000 - 10,000 min-1 (in steps of 500 min-1)Rotor peripheral speed22 ..72 m/sTypes of rotorsstandard / distanceMaterial of grinding toolsrotor and sieves of stainless steelSieve sizestrapezoid holes 0.08 / 0.12 / 0.20 / 0.25 / 0.35 / 0.50 / 0.75 / 1.00 / 1.25 / 1.50 / 2.00 mm

round holes 3.00 / 4.00 / 10.00 mmHinged hopperremoveable hopperDust extraction unitoptional cycloneCollector capacity5 l / optional: 30 lDrive3-phase motorElectrical supply data200-240 V, 50/60 HzPower connection1-phaseEngine brakeyes, electricProtection codeIP 41Power consumption2.5 kWW x H x D closed600 x 1200 x 700 mm (with base frame)Net weight~ 60 kg (with base frame)StandardsCE

Specifications

| Manufacturer | Retsch |

| Model | SR300 rotor beater mill |

| Condition | Used |

| Stock Number | BM5615 |