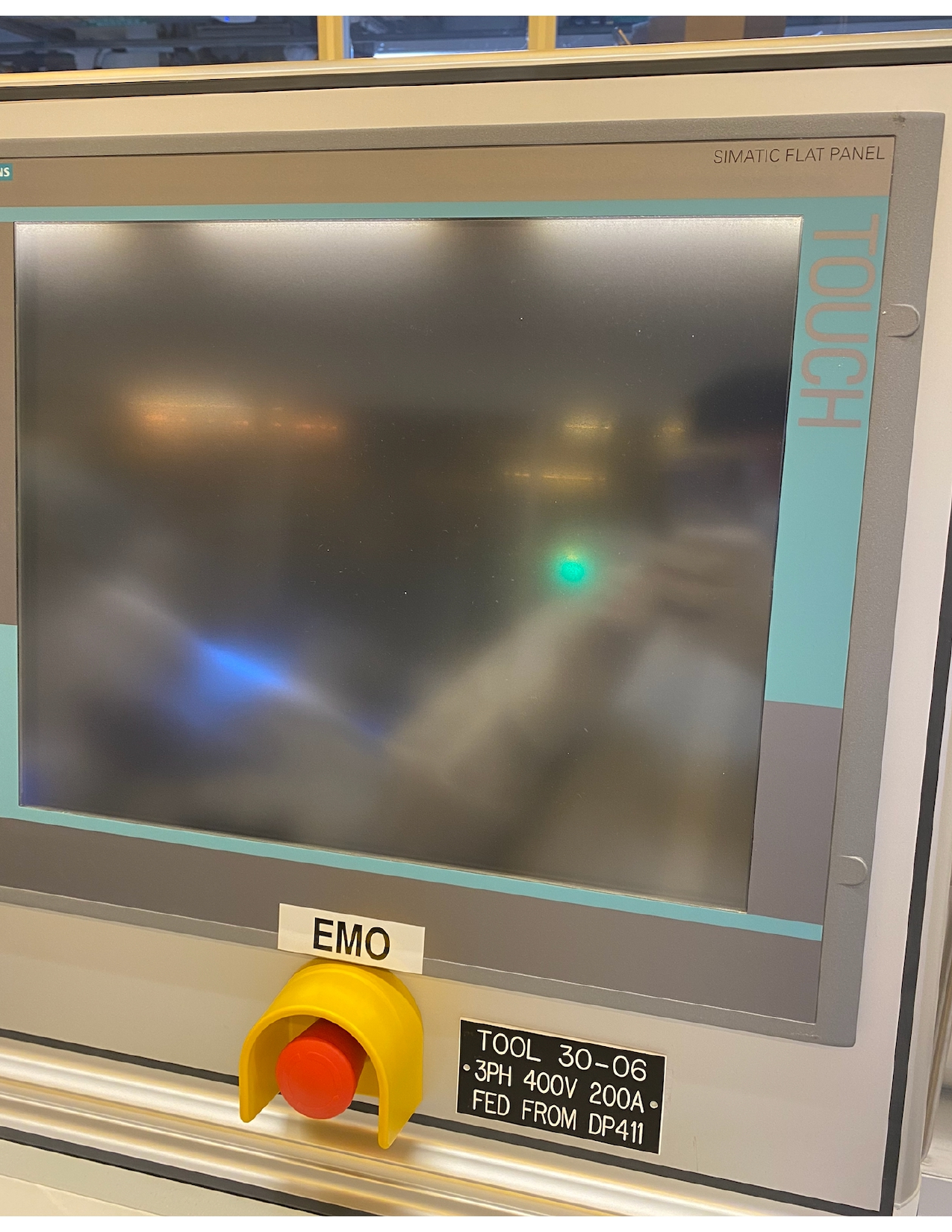

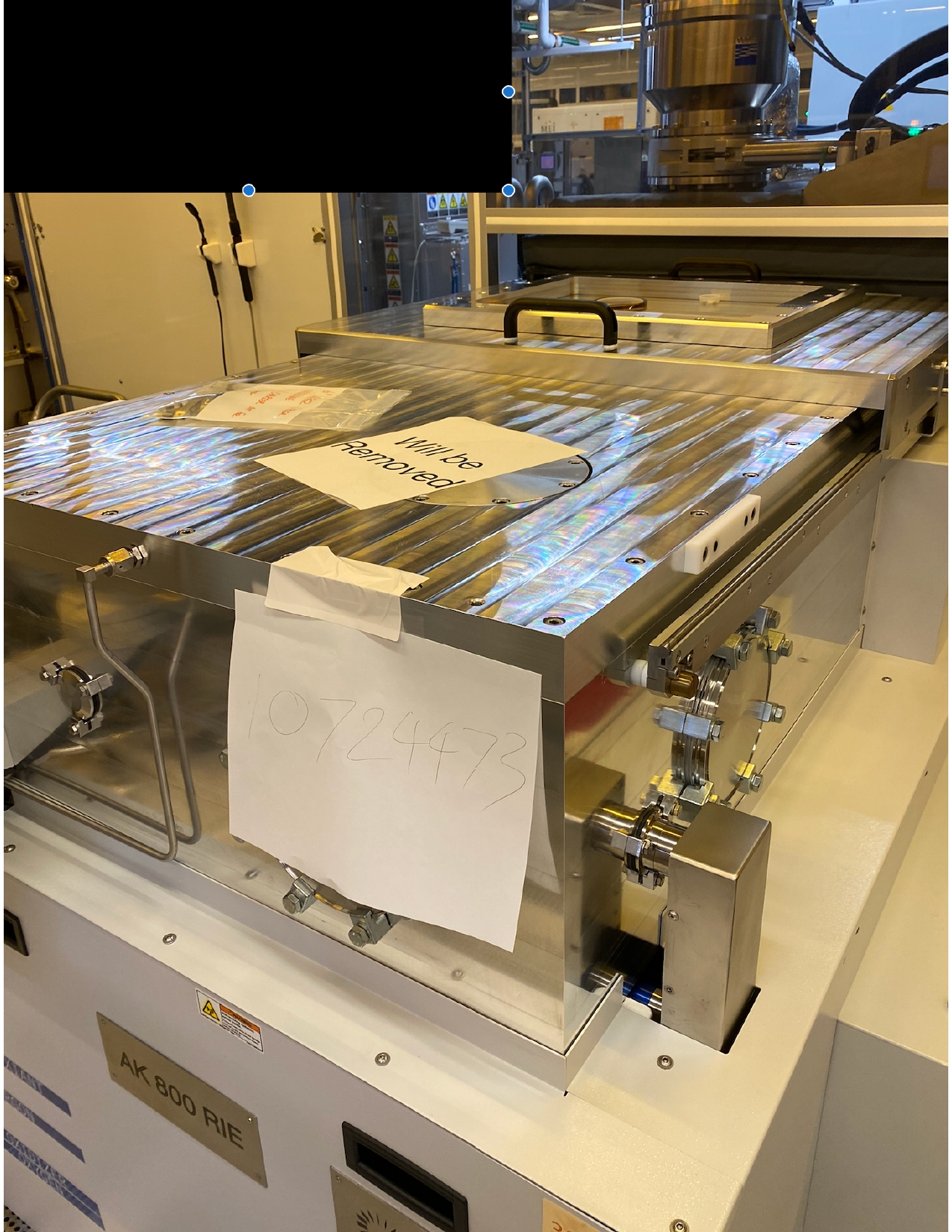

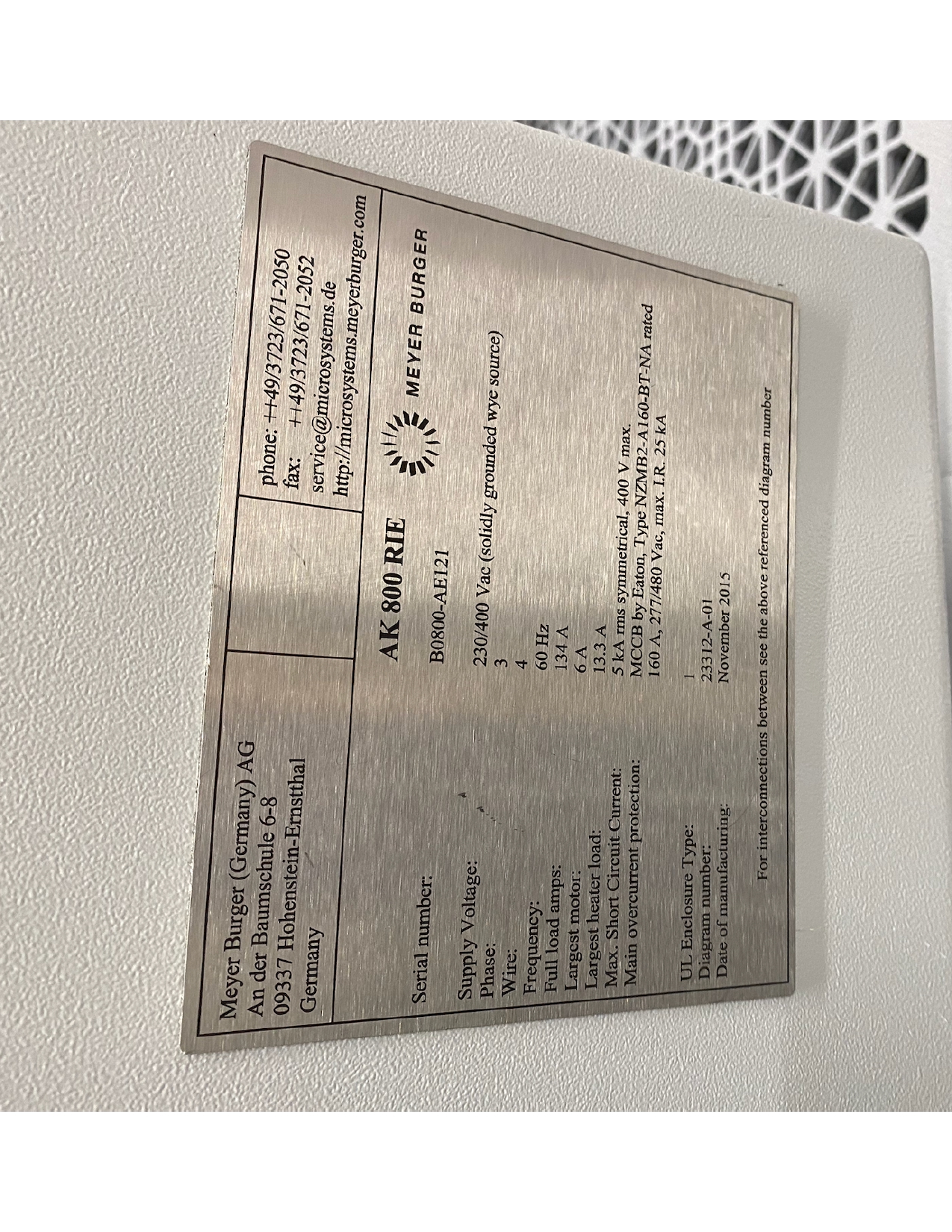

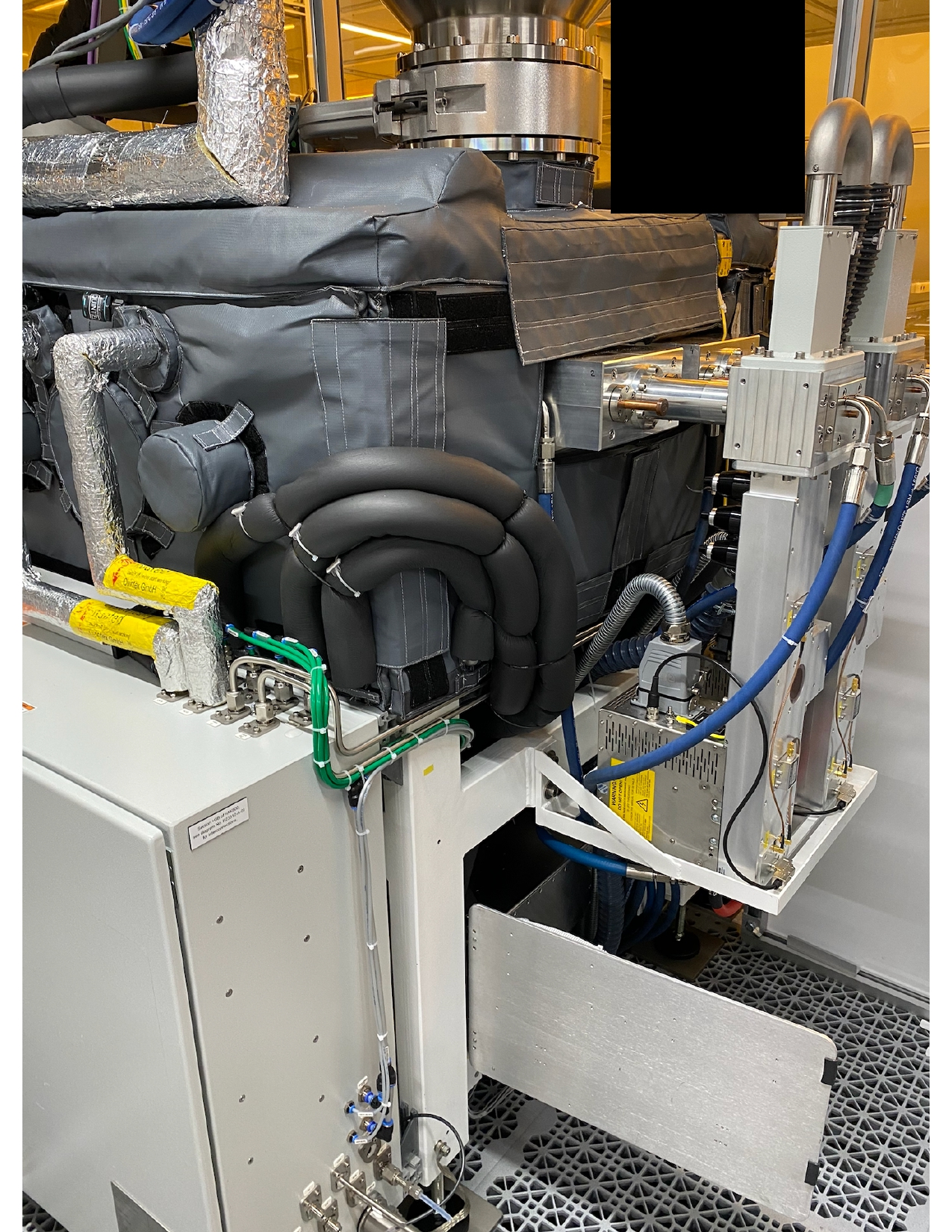

2015 Meyer Burger AK 800 RIE System

2015 Meyer Burger AK 800 RIE System

Contact us for price

or

Call +353 (0) 87 192 1110

Description

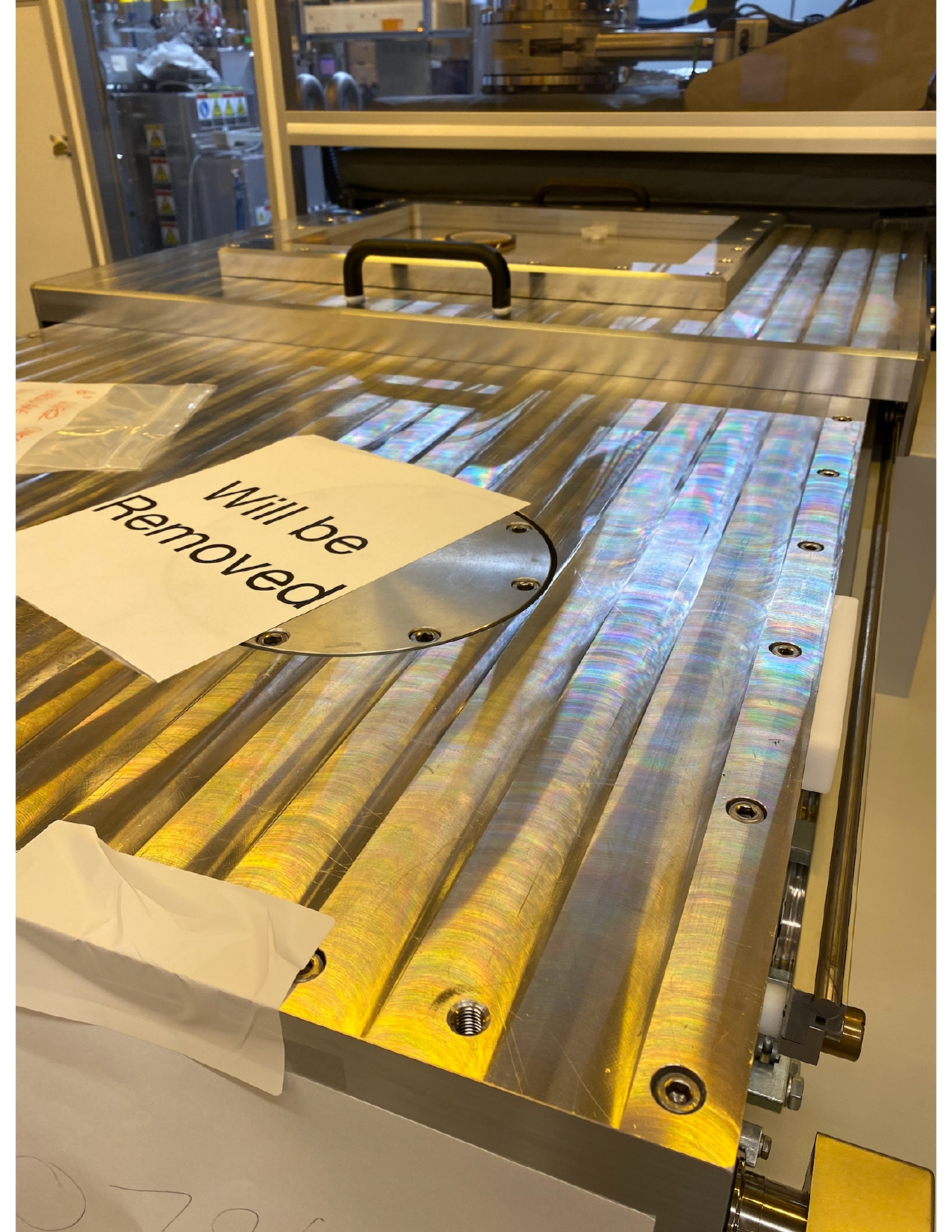

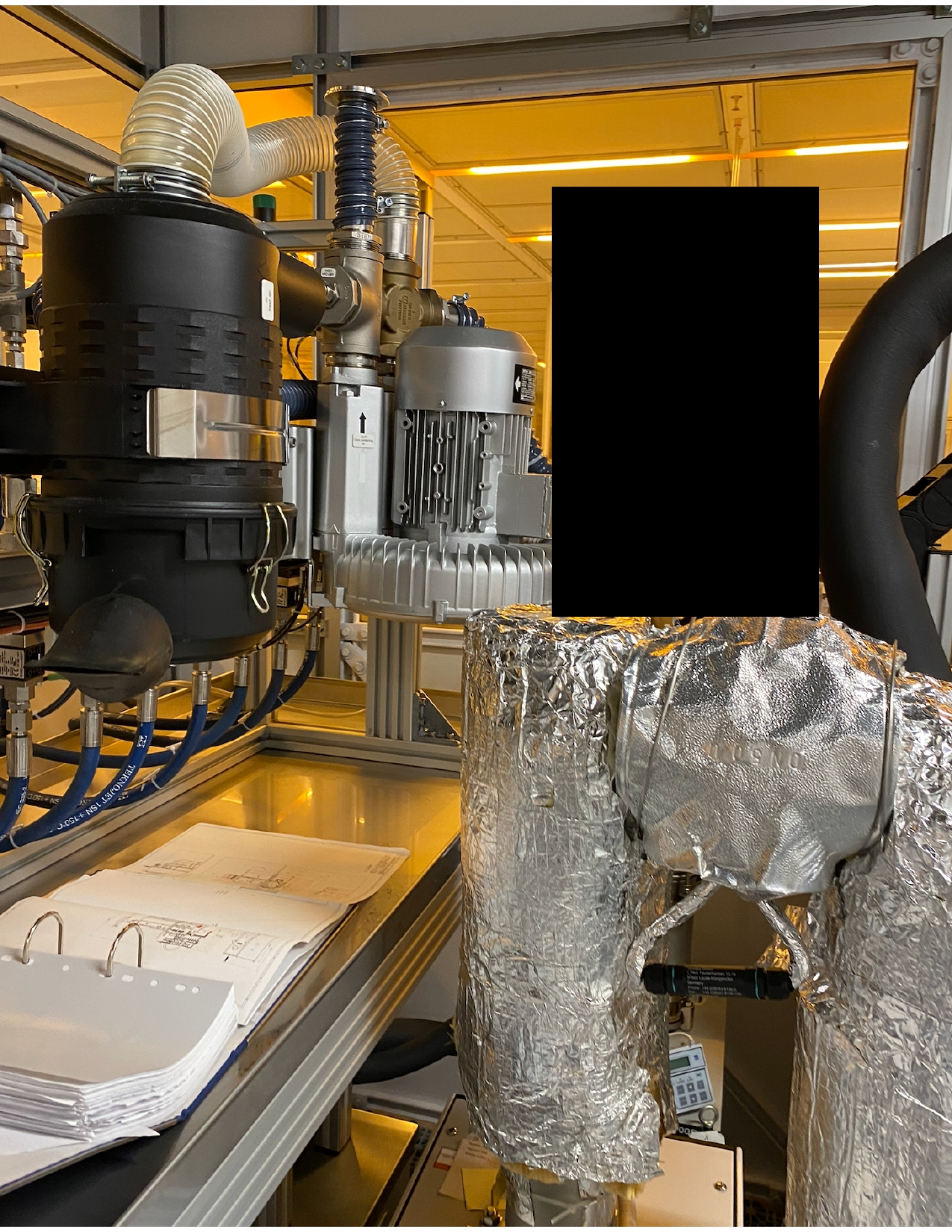

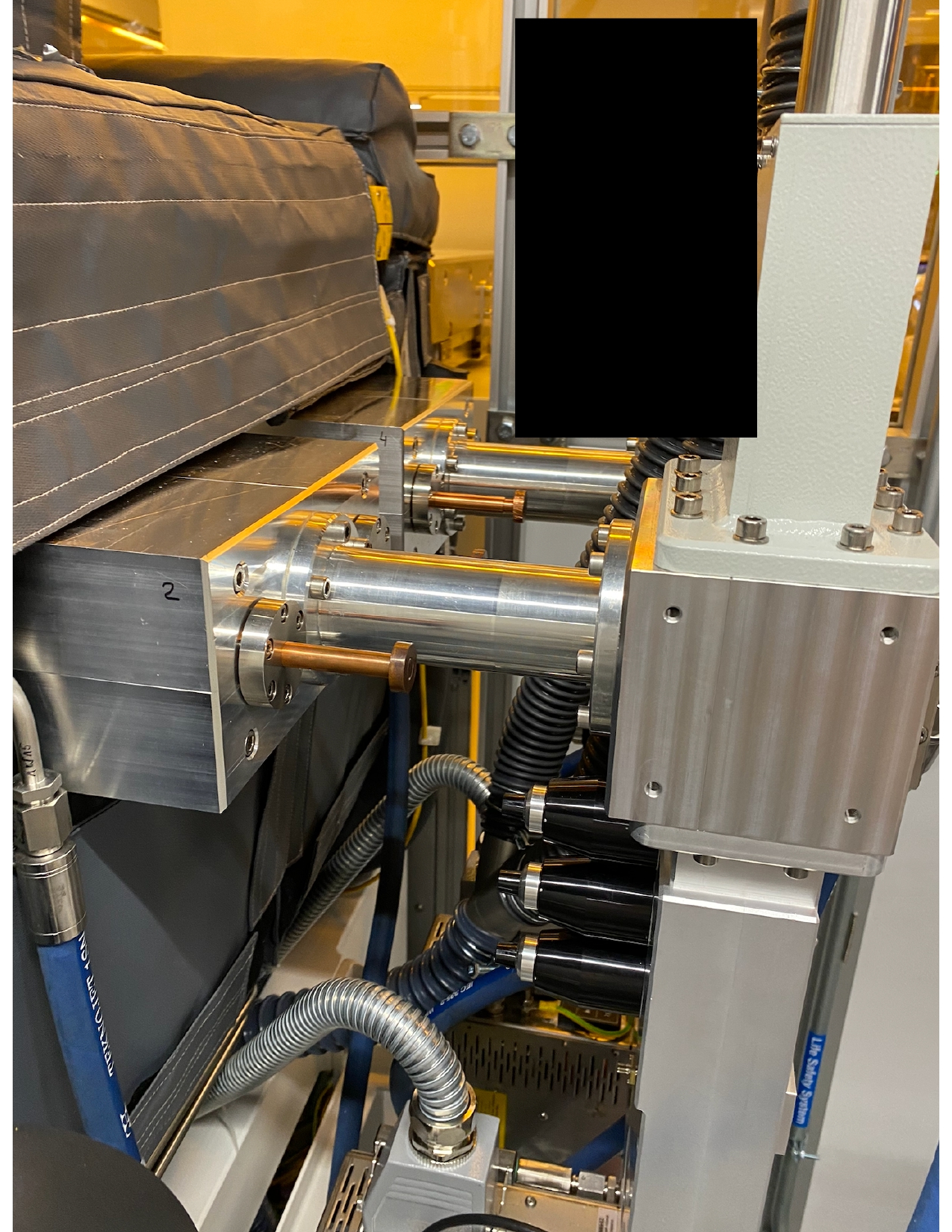

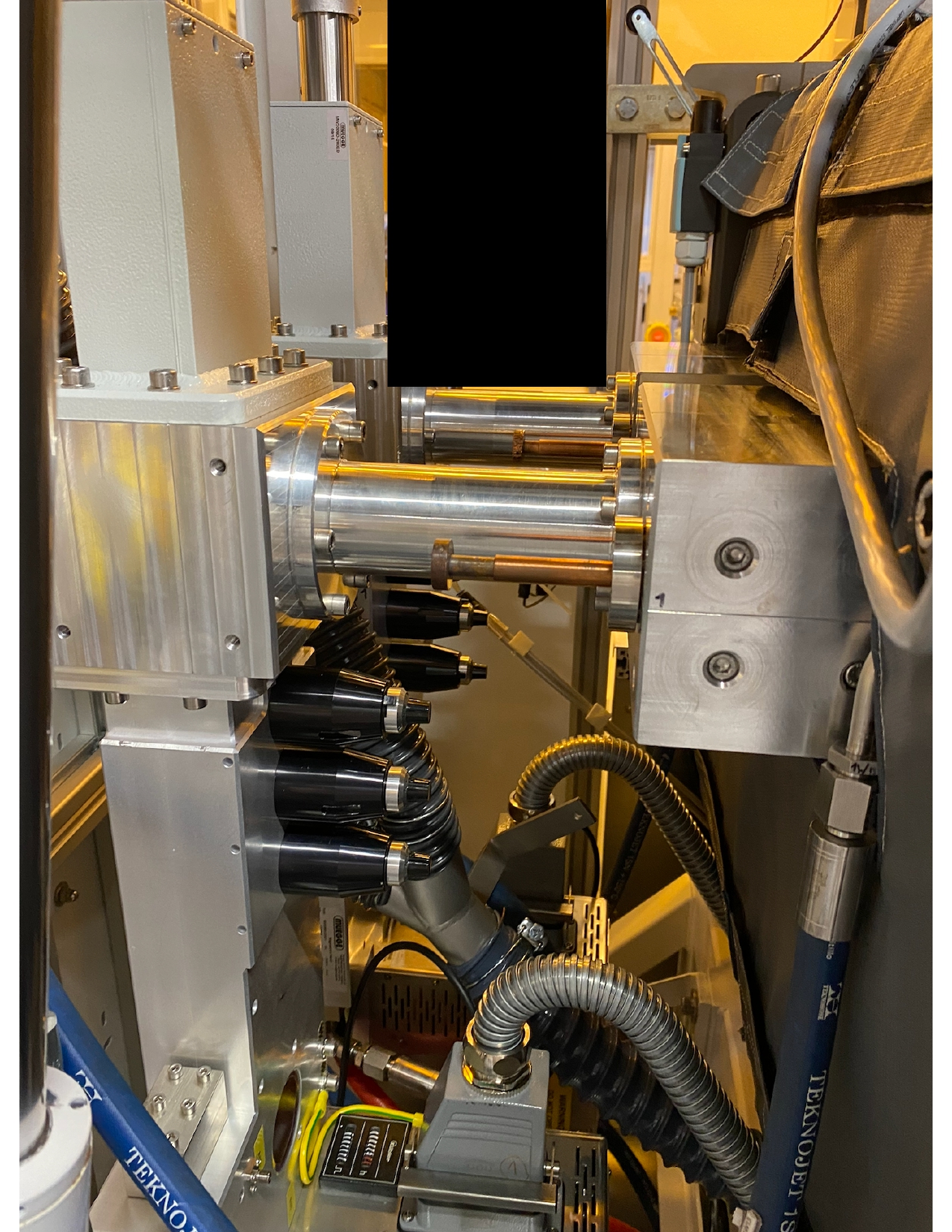

Meyer Burger AK800 Configuration overview

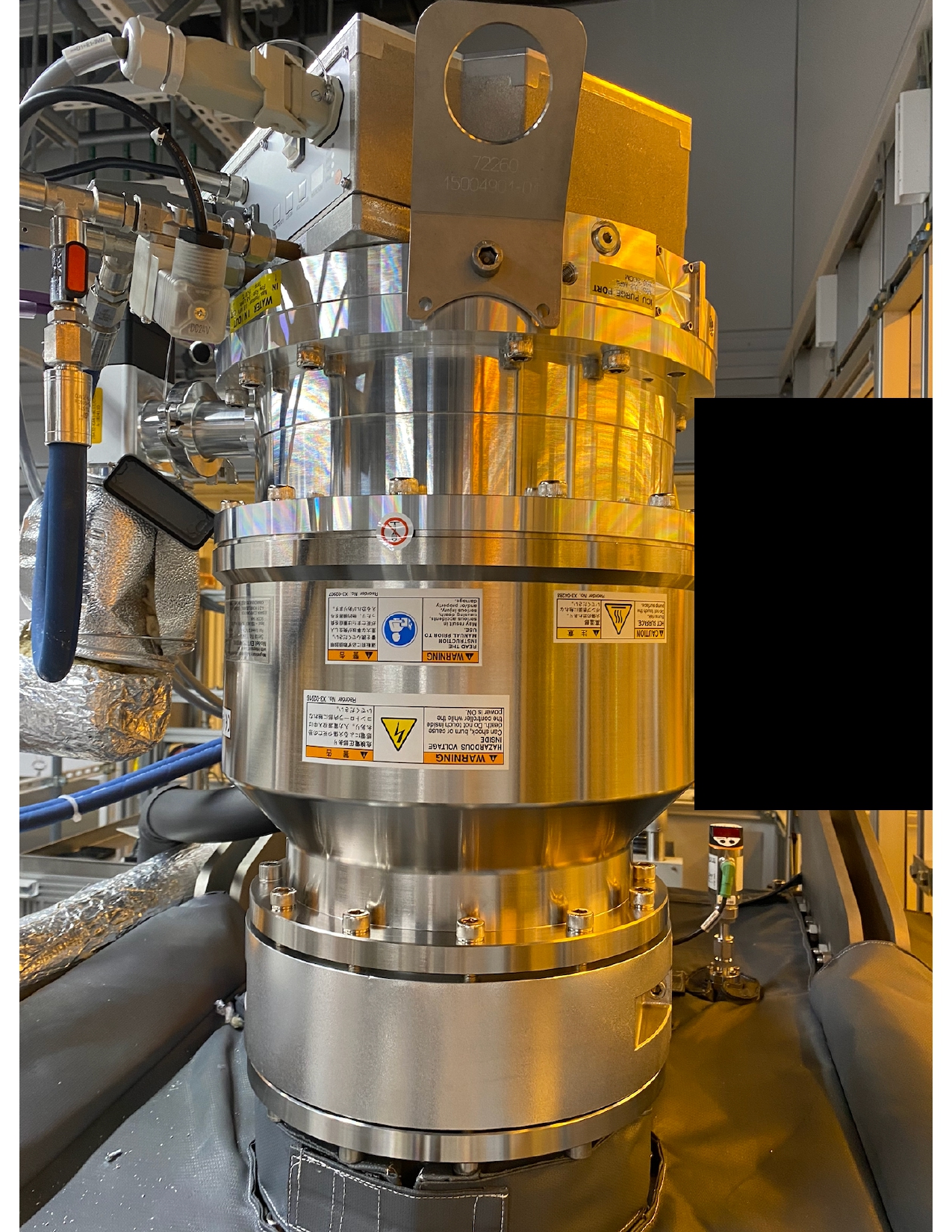

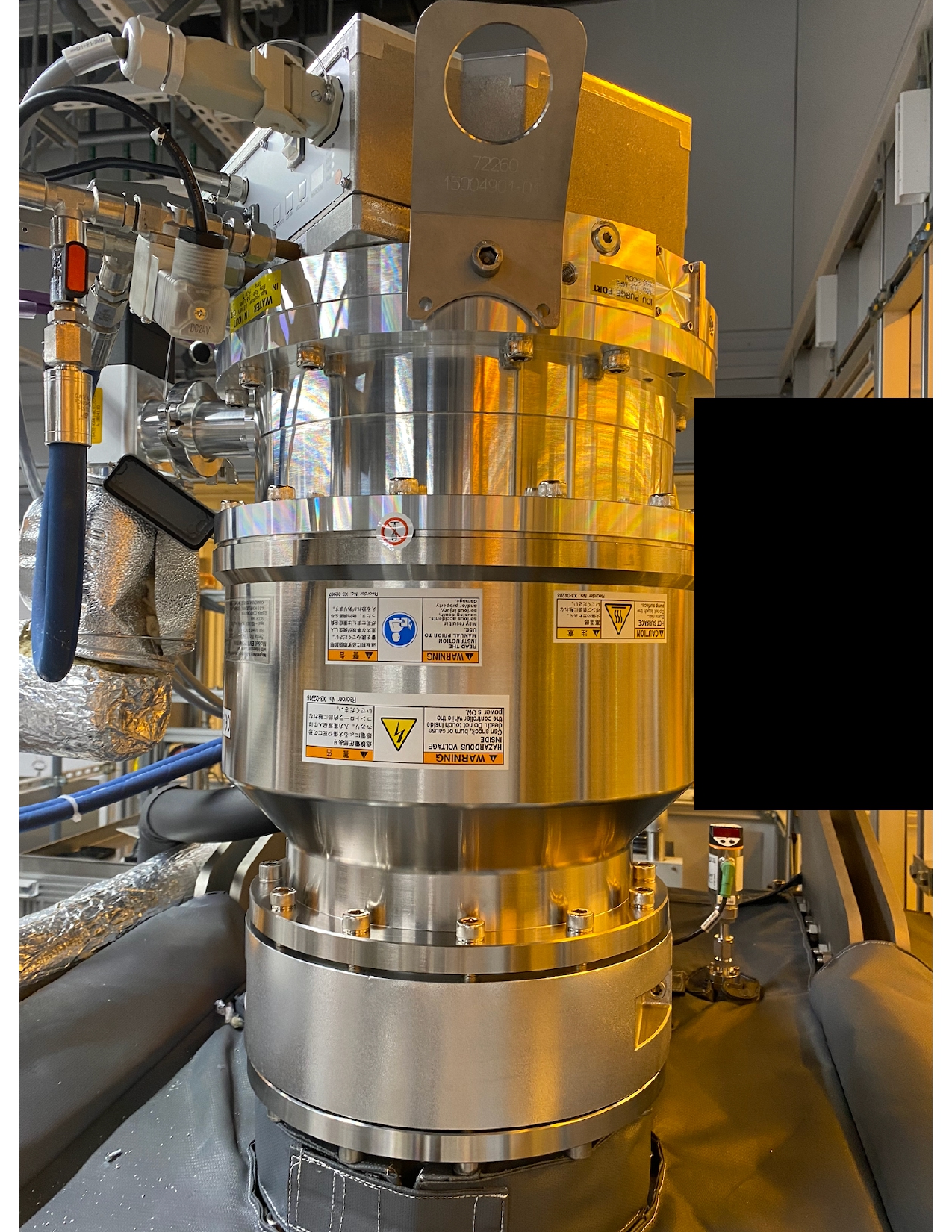

• Versatile ICP etcher to anisotropically etch most thin-film materials

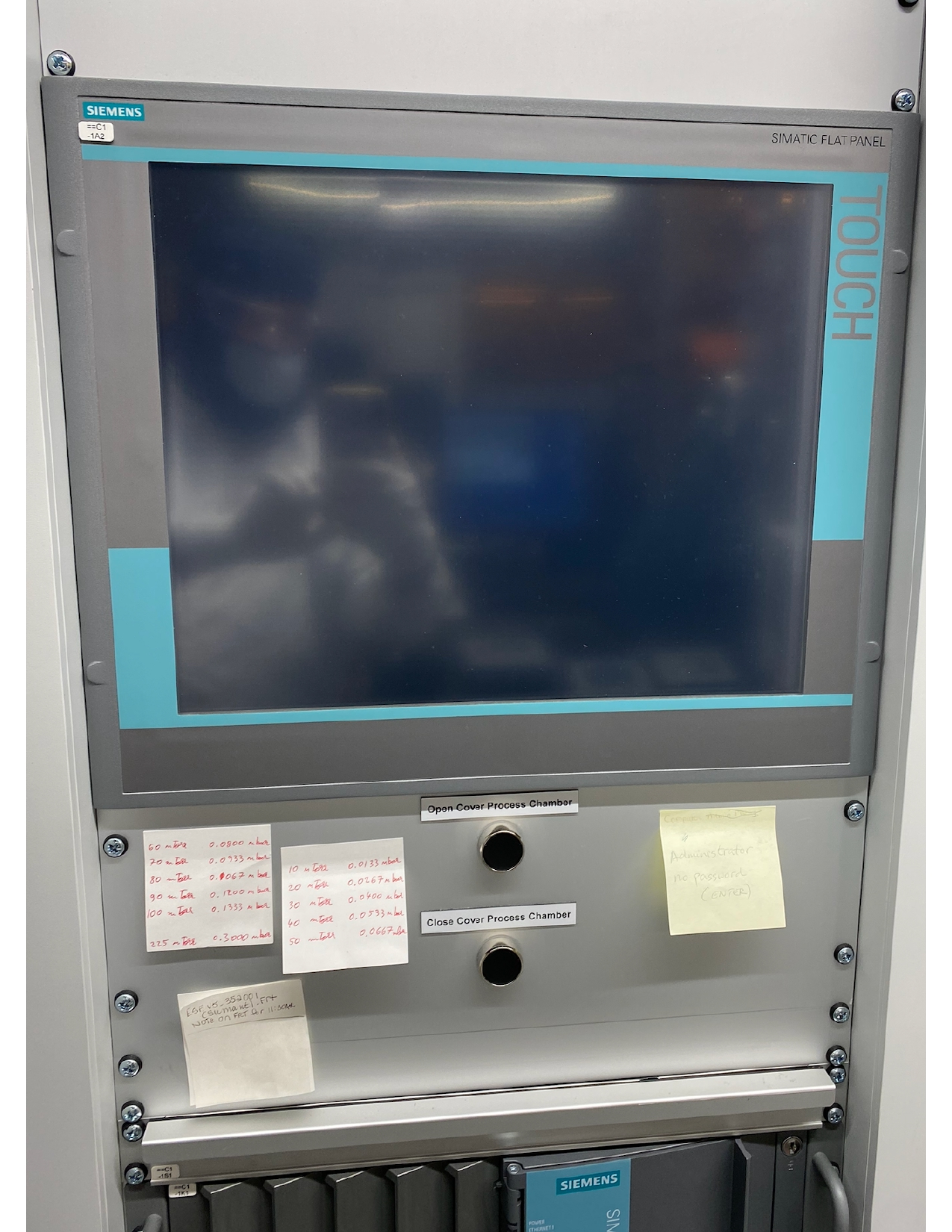

• Two 5 kW 2.45 GHz microwave power supplies coupled to 4 independent waveguides deliver high-density free radicals for a gentle chemical etch

• 13.56 MHz power supply powers the cathode to provide bias for anisotropy

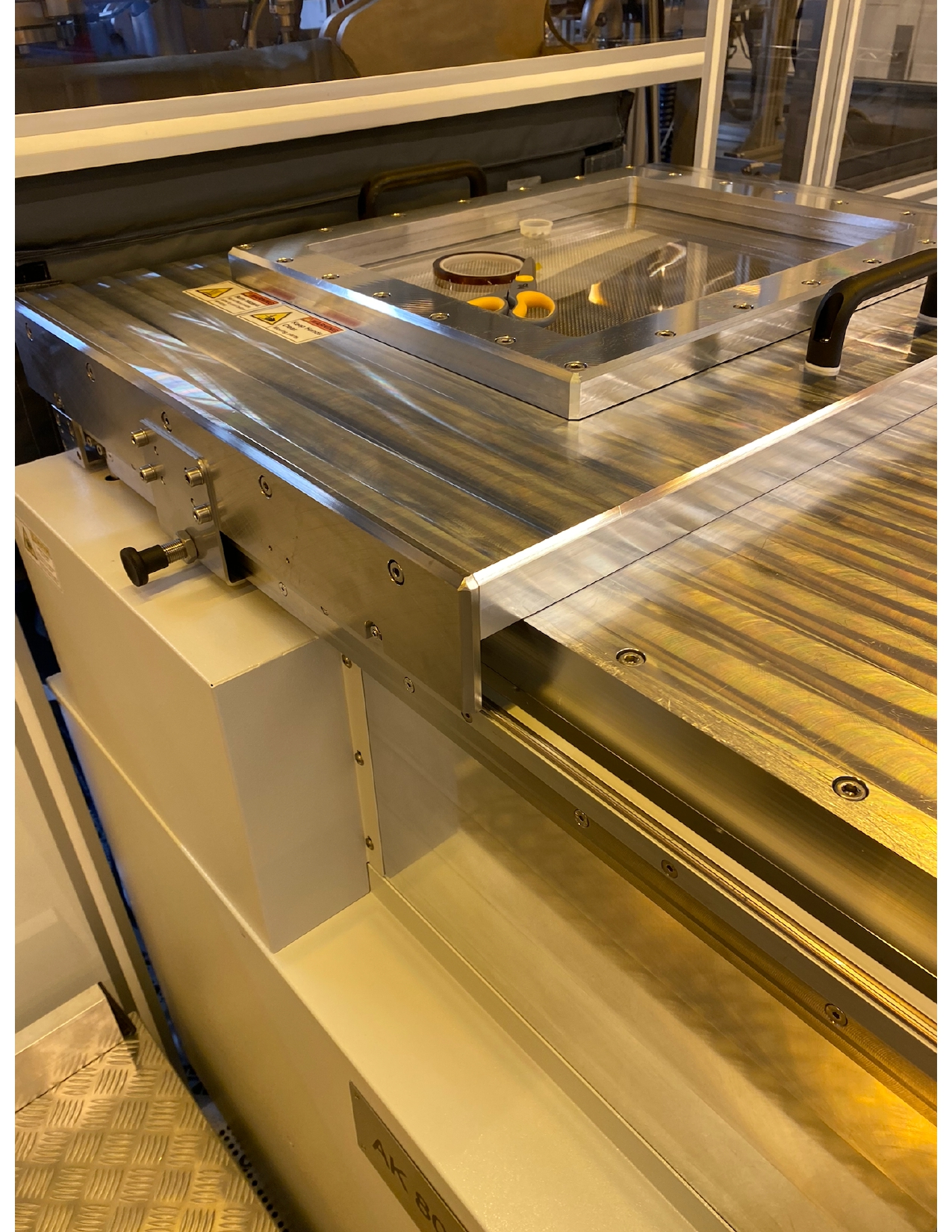

• Manual load (3) 6-inch wafers onto the carrier, then into L/L

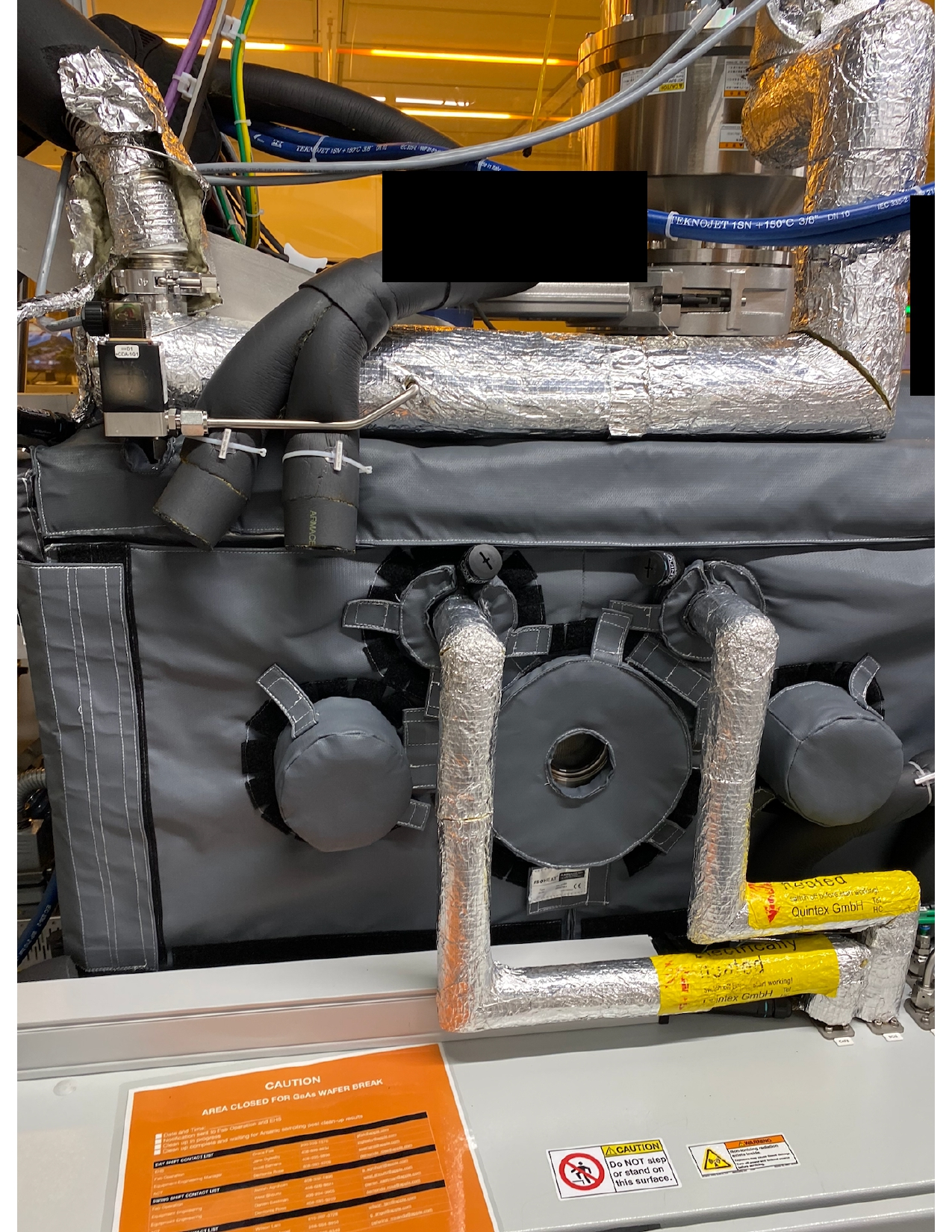

• L/L & process chamber equipped with roughing pump and turbo

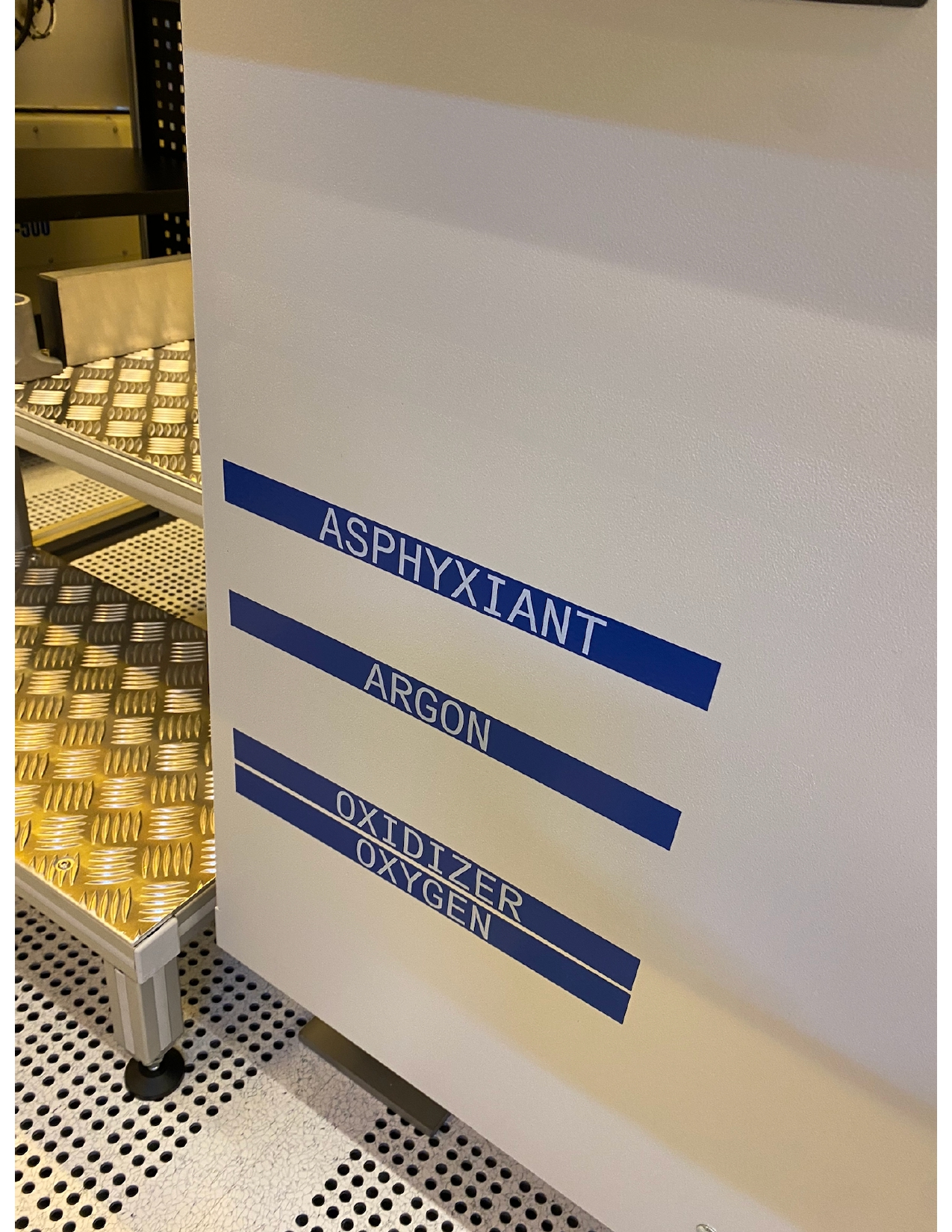

• Process gases BCl₃, Cl₂, CF₄, SF₆, C₄F₈, O₂, and Ar

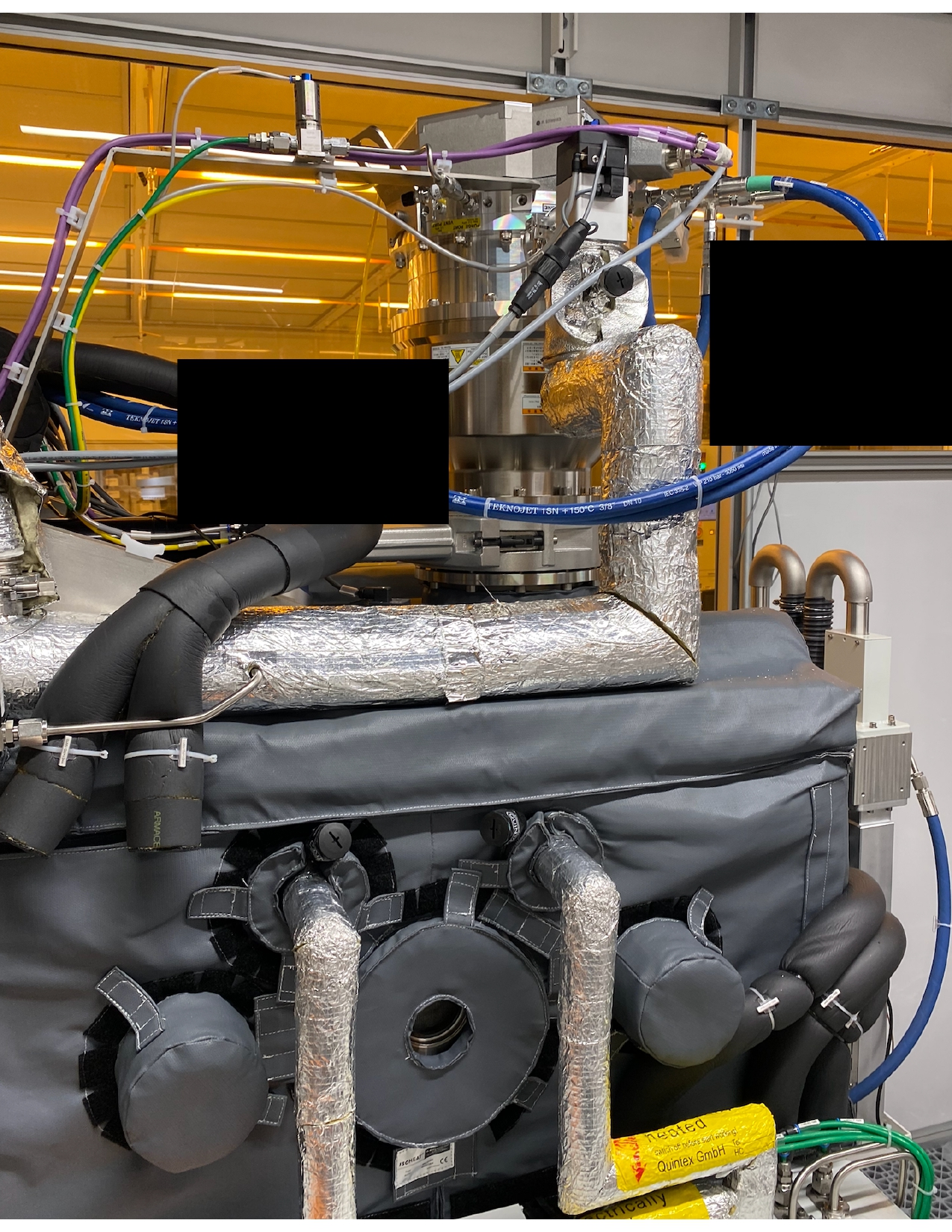

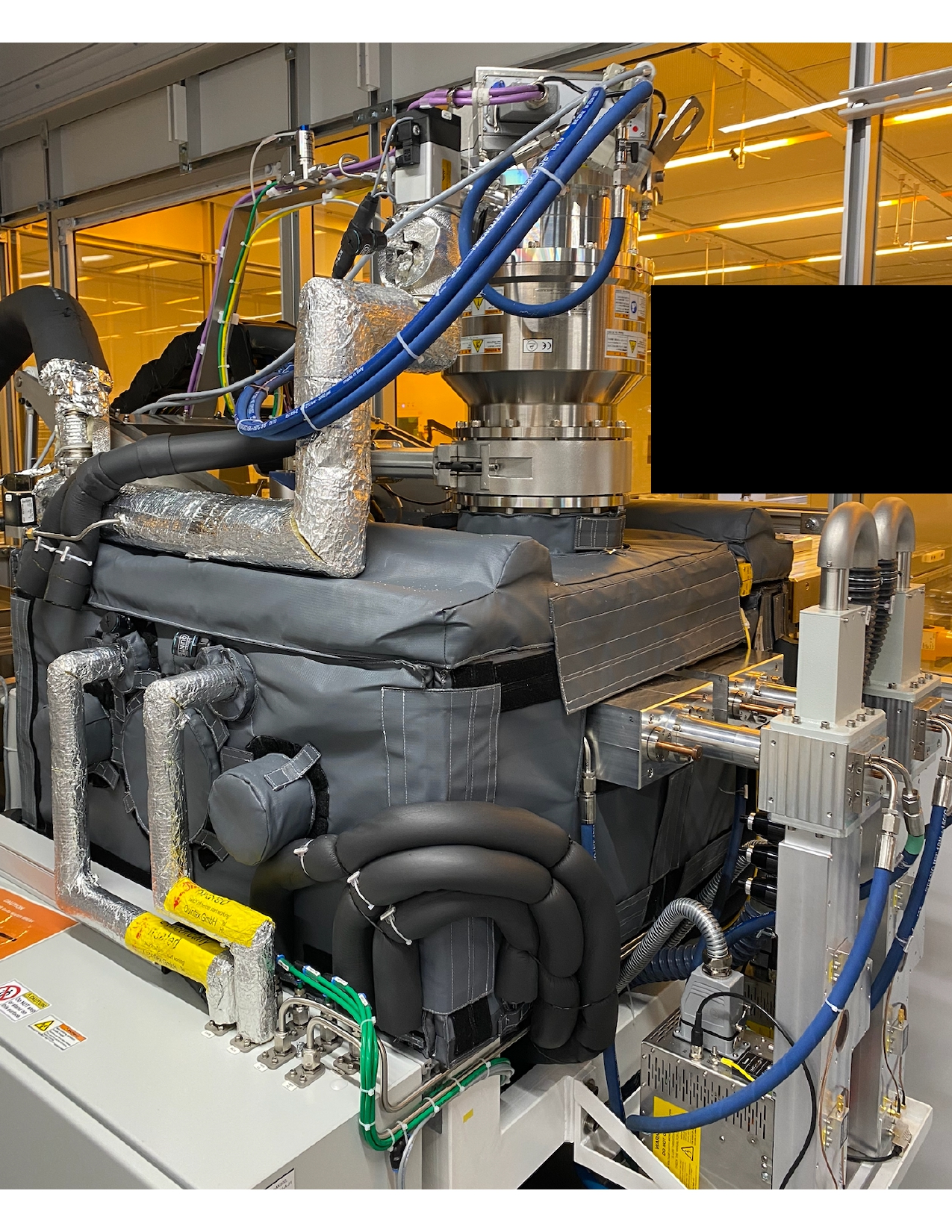

The Meyer Burger AK800 RIE system is for semiconductor and photovoltaic manufacturing, particularly involving processes like Reactive Ion Etching (RIE).

Overview of the AK800 RIE system

- Reactive Ion Etching (RIE): RIE is a dry etching technique that uses chemically reactive plasma to remove material from a substrate.

- Application: Meyer Burger (Germany) AG — BU MicroSystems, the division responsible for the AK800, supplied technology for the high-precision coating, structuring, and processing of surfaces. These systems were primarily used in the semiconductor and photovoltaic industries.

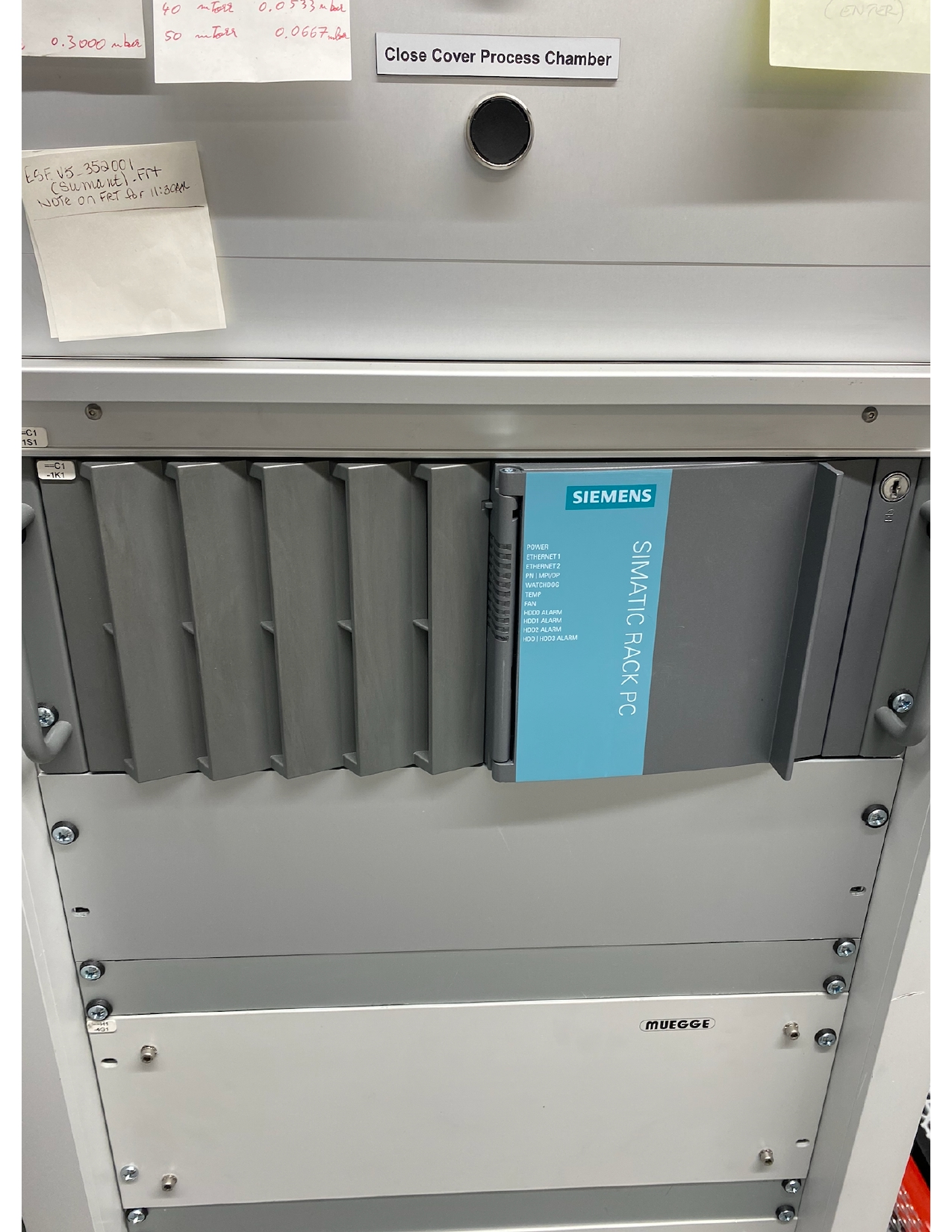

- Technology: The system featured a modular design, enabling it to be adapted for various surface treatment methods, including RIE, PECVD (Plasma-Enhanced Chemical Vapor Deposition), and ion beam etching/deposition.

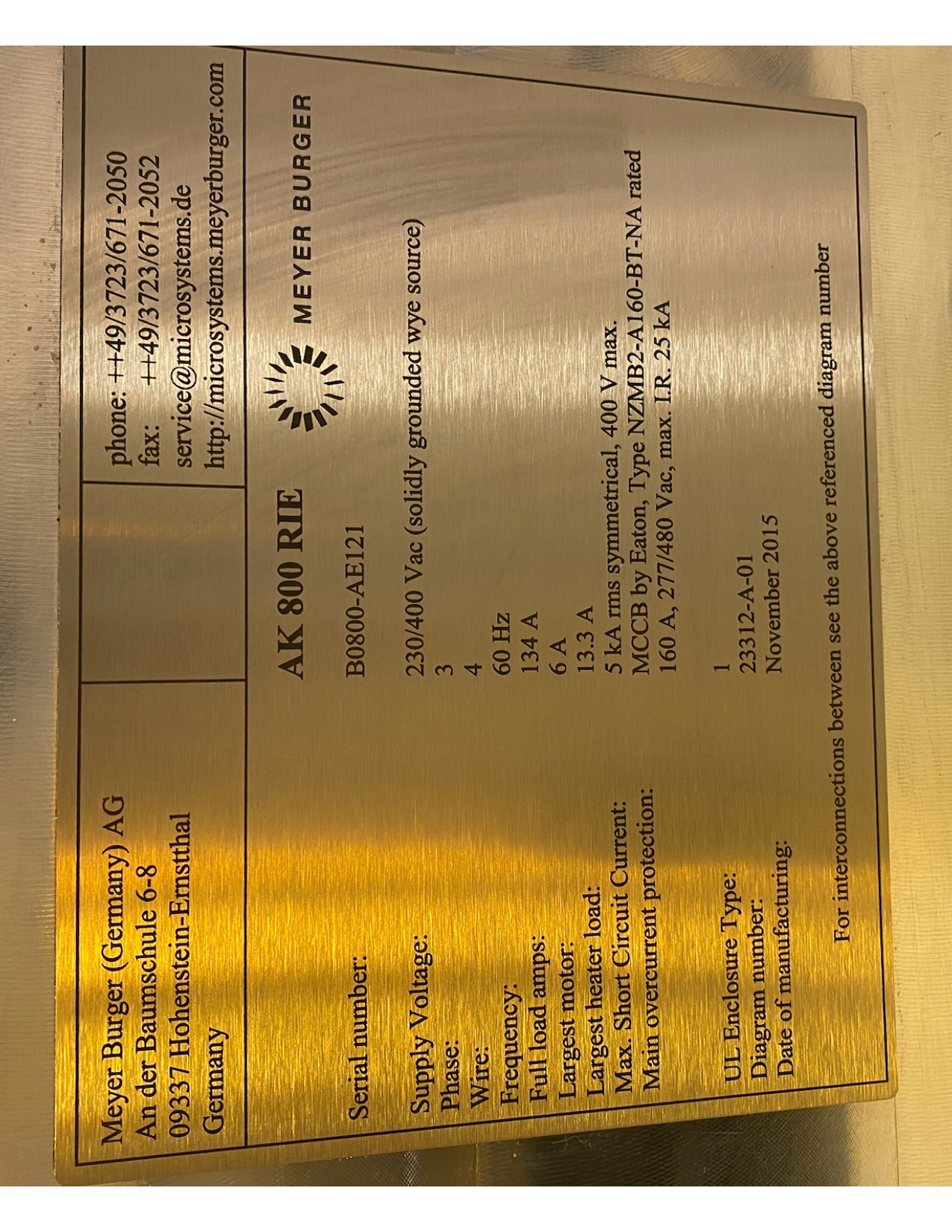

Specifications

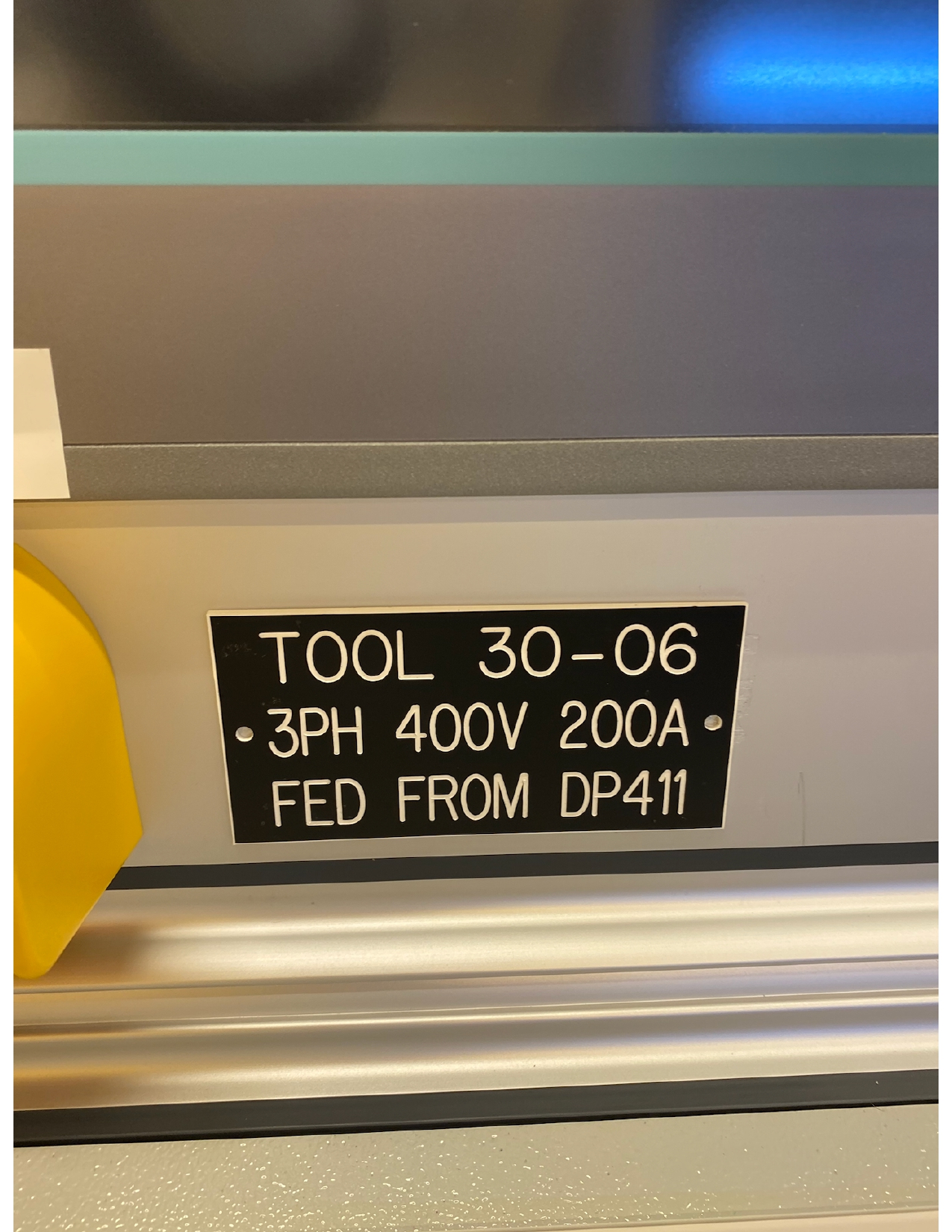

| Manufacturer | Meyer Burger |

| Model | AK 800 RIE System |

| Year | 2015 |

| Condition | Used |

| Stock Number | GOD23082023720223592 |