2003 TEL ACT-12 Local System Clean Track System

2003 TEL ACT-12 Local System Clean Track System

Contact us for price

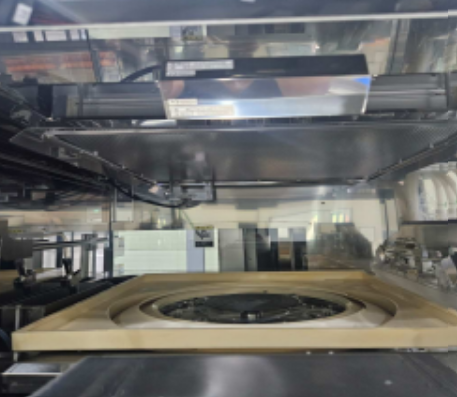

Description

2 available

https://www.tarasemi.com/listings/7667648-used-tel-act-12-i-line-system-clean-track-system

Further details in images

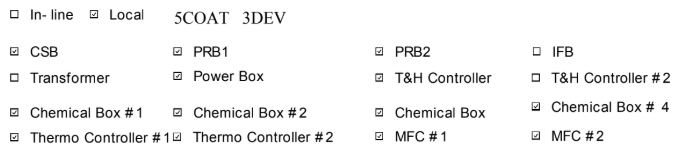

1. DESCRIPTION

1-1. Number of Machine : E230673

1-2. Left to Right

1-3. MODEL : Clean track ACT-12

1-4. WAFER & CARRIER TYPE : 12", FOUP, 25 Slots

1-5. System Power Rating : AC 208V , 3-Phase for System

1-6. Loading Configuration : 4 Loader

1-7.Software Version : Power off

1-8.Main controller : #4 Controller

2. Main system

1)Main frame with system controller

2) Carrier station

- Type: FOUP Cassette Type

- 4 Cassette Stage

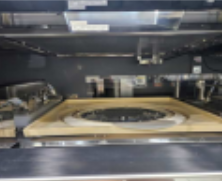

3) Coater unit

- 8 dispense nozzle with temperature controlled lines for etch unit

- Koganei Pump

- Rinse nozzle : back/ EBR / solvent bath for etch unit

- Rinse system : 3 liter 2Tank Buffer tank system

- P.R Suck-back Valve Type : Air ope Suck-back valve

- Programmable side rinse

- Drain: Local pump drain

4) Tarc Coater unit

- 4 dispense nozzle with temperature controlled lines for etch unit

- Koganei Pump

- Rinse nozzle : back/ EBR / solvent bath for etch unit

- Rinse system : 3 liter 2Tank Buffer tank system

- P.R Suck-back Valve Type : Air ope Suck-back valve

- Programmable side rinse

- Drain: Local pump drain

5) Barc Coater unit

- 8 dispense nozzle with temperature controlled lines for etch unit

- Koganei Pump

- Rinse nozzle : back/ EBR / solvent bath for etch unit

- Rinse system : 3 liter 2Tank Buffer tank system

- P.R Suck-back Valve Type : Air ope Suck-back valve

- Programmable side rinse

- Drain: Local pump drain

5) NEW Developer unit

- NLD nozzle for each unit

- 1 stream nozzle for DI rinse and 1 points for back side rinse on each unit

- Developer system : 3 liter 2Tank Buffer tank system

- Developer temperature control system

- Drain: direct drain

6) InterFace type : None

7) Adhesion Unit 1EA

- 100% sealing closed chamber(Built-in hot plate)

- HMDS tank with float sensor in system

8) High Exhaust LHP Process Station (HEL) 4EA

9) Heater Cover Type Hot Plate Process Station (HCH) 2EA

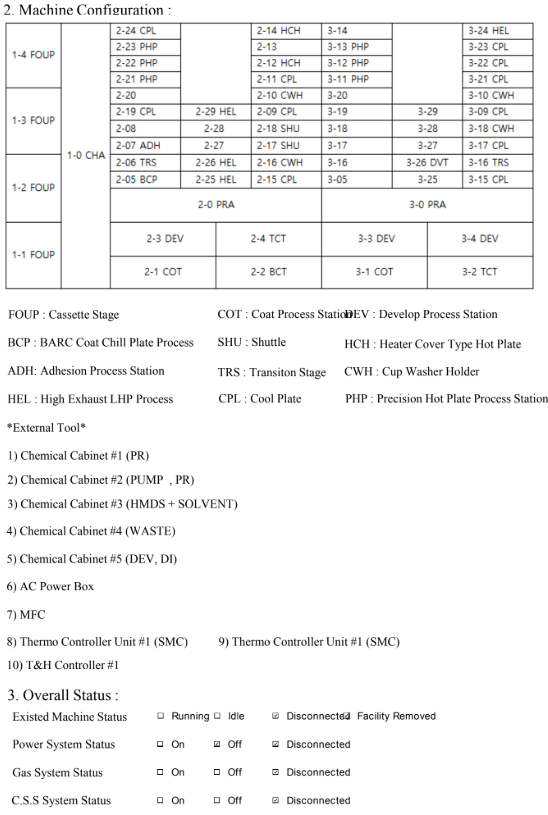

4. Machine Detail Check

10) Chill Plates (CPL) 11EA

11) Precision Chilling Hot Plate Process Station (PHP) 6EA

12) BCP Module 1EA

13) TRS Module 2EA

14) DVT Module 1EA

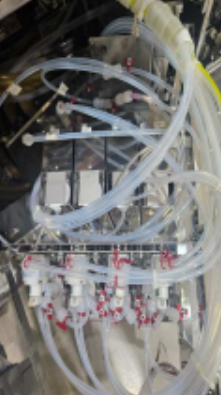

15) Chemical Cabinet #1 : PR

16) Chemical Cabinet #2 : PR & PUMP

17) Chemical Cabinet #3 : HMDS & SOLVENT

18) Chemical Cabinet #4 : WASTE

19) Chemical Cabinet #5 : DEV.DI

20) Temperature&Humidity controller 1EA

- Type: ESA-16

21) TEMP Control Unit(TCU) 2EA

- Type: TEL OEM

22) AC Power Box

23) MFC : 2port

Specifications

| Manufacturer | TEL |

| Model | ACT-12 Local System Clean Track System |

| Year | 2003 |

| Condition | Used |

| Stock Number | BM5454 |